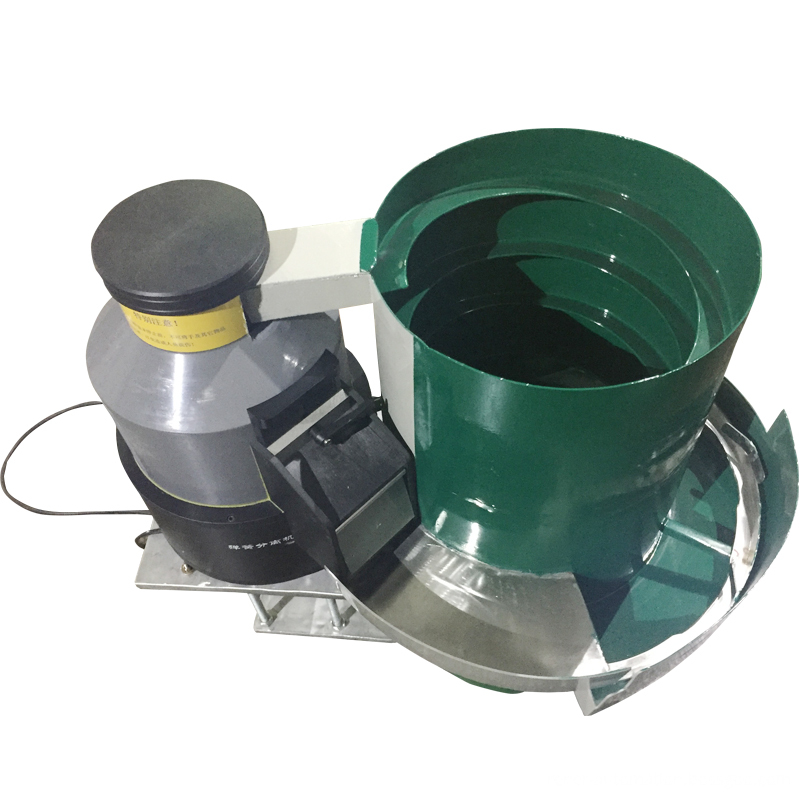

Spring Vibratory Bowl Feeder Design

Basic Info

Model No.: RESF005

Product Description

Vibratory Bowl Feeder Design

This Spring Vibrating Bowl automatically arrange,select direction through vibratory bowl, discharge and feed to the machine.The Vibratory Bowl Feeder Design includes separator, vibration disk, direct vibration, frequency modulation voltage controller, cylinder, fixed bracket, bottom board, etc.

1.Machine Function:

Spring Separator to solve the best weapon for small spring up!! This feed machine is suitable for entanglement in small spiral spring together after centrifugal vibration mode to be separated one by one,separation rate over 95%.

| |||||||||||||||

| 2. Machine Parameters: Spring diameter 2-30mm

| |||||||||||||||

| |

Application of the industry

Due to the wide range of products, the application of non-standard automation equipment has also been widely used in the application. The main application of the industry are:

1, the automobile manufacturing industry of automobile parts manufacturing and installation; production conveying and packaging

2, the food industry;

3, electronic and electrical appliances production line products transportation;

4, logistics warehousing facilities also has a wide range of applications;

5, processing and manufacturing industry assembly application.

3. About us:

Dongguan Rener Automation Technology Co., Ltd. is a high-tech enterprise engaged in R & D, industrial non-standard machinery and equipment production, sales and service automation.Our products are widely used in automatic production of standard fasteners, hardware accessories, auto parts, electronic parts, electrical appliances, plastic hardware, locks, medical equipment accessories, cosmetics, sanitary products and other industries. Undertake mobile phone connector, automotive, medical, hardware, wire, all kinds of consumer electronic products, sanitary products and other non-standard automation equipment R & D project development, to undertake a variety of plastic hardware products production line, assembly line, automatic machine manufacturing, design various automation solutions.Effective for the enterprises to solve the problems in high cost, low efficiency and serious quality, recruitment difficulties, labor trouble etc...For all enterprises to save resources, improve efficiency, achieve social harmony and win-win and customer.

Our main products: plastic & Hardware assembling machine, sanitary assembly machine, automatic locking screw machine, spring separating feeder machine, we developed a number of sanitary assembly line has been successfully put into production in the Middle East.

We have experienced technical backbone and a strong engineering team, and provide overseas machine commissioning and overseas training experience and service, make the enterprise production line put into production, we provide technical support and thoughtful pre-sale customer service for customers in the industry field, we will make unremitting efforts to strive for the majority of customer service. Dongguan Rener automation technology limited company's good faith, strength and quality of products recognized by the industry. Welcome friends from all world of life come to visit, guidance and business negotiation

4. Customer Service:

1) Warranty period:1 years (Non-human damage and other factors)

2) Provide logistics, customs service and foreign installation ,commissioning and operator training service for the machine.

After services:

FAQ

1. How long will your engineer reach our factory?Within one week after machine arrival your factory.

2. How many days will you finish installing & commissioning ?

We will finish installation,commissioning and training within 15-25days.

3. What should we charge for your engineer?

You should charge for the cost of our engineer's visa, air tickets, hotel, food, and also their salary 50USD one day per person.

4. How long is your machine's warranty period?

All our machine have one year guarantee, starting from finished installation.

5. How could we do after one year warranty period?

We also can do service for you, but you need pay salary for my technician 80USD/day.

6. How could we do if the parts broken within warranty?

We would express the free replacement parts during the warranty date.

7. Does your engineer understand English?

Our engineers understand a little English. All of our engineer have more than five years machine installation experience. In addition, they can use body language to communicate with customer.

Pls Note:

Product Categories : Automatic Feeding Machine > Spring Feeder Machine